锌铝镁彩涂卷打入汽车零部件制造领域

锌铝镁彩涂板是一种新型的涂层材料,具有优异的耐蚀性和焊接性能,特别是在耐盐雾和海洋气候条件下。该产品的性能优于传统的涂料产品。可广泛应用于光电、畜牧、通讯、道路交通、家电、汽车等领域,符合钢铁材料绿色环保的发展趋势。

Zn-Al-Mg合金镀层是由Zn、Al和Mg高温凝固形成的。

锌铝镁彩涂板该组织由致密的Zn、Al、zn2mg三元共晶组织组成,在钢板表面形成致密的阻挡层,有效防止腐蚀因素的渗透。镀锌铝镁钢板具有优良的耐蚀性,是热镀锌钢板的10~20倍,是热镀锌铝(5%)合金钢板的5~8倍。

Zn-Al-Mg钢制品的显著性能包括耐磨性、耐高温性和涂层性能。镀锌铝镁制品具有较高的表面硬度。镀锌铝镁制品的初始动摩擦系数与镀锌铝镁制品相似,但随摩擦次数的增加变化不大。低摩擦系数有利于冲压变形。根据部分零件的高温装配要求(350℃), 进行了耐高温试验。结果表明,热处理至380℃时,镀锌铝镁合金表面无熔化现象℃. 锌铝镁涂层钢板的镀层性能与纯锌基本相同。可用于电泳、后喷涂和彩色涂装。

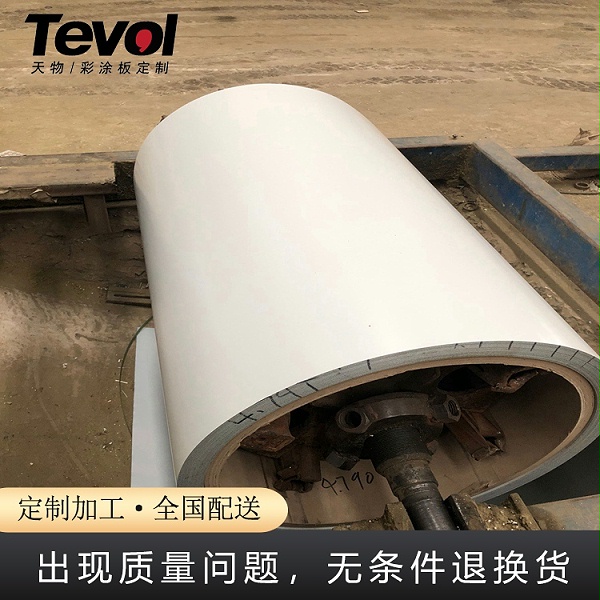

锌铝镁彩涂板

产品主要应用于土木工程(龙骨吊顶、穿孔板、电缆桥架)、农畜产品(农畜养殖大棚、钢结构、钢构配件、温室、投料设备)、铁路、公路、电力通信(输变电高低压开关柜、箱式变电所本体),汽车电机、工业制冷(冷却塔、大型室外工业空调)等行业,都得到了广泛的应用。

Zinc aluminum magnesium product is a new type of coating material, which has excellent corrosion resistance and welding performance, especially in salt fog resistance and marine weather conditions. The performance of the product is better than that of conventional coating products. It can be widely used in photoelectric, animal husbandry, communication, road traffic, home appliances and automobile fields, which is in line with the development trend of green and environmental protection of steel materials.

Zinc aluminum magnesium color coated coil

The alloy coating of Zn Al Mg is formed by high temperature solidification of Zn, Al and Mg. The structure is composed of dense ternary eutectic structure of Zn, Al and zn2mg, which forms a dense barrier on the surface of the steel plate to effectively prevent the penetration of corrosion factors. Galvanized Al Mg steel sheet has excellent corrosion resistance, which is 10-20 times of that of hot-dip galvanized steel sheet and 5-8 times of that of hot-dip galvanized Al (5%) alloy steel sheet.

The remarkable properties of Zn Al Mg steel products include friction resistance, high temperature resistance and coating property. Zinc coated Al Mg products have higher surface hardness. The initial dynamic friction coefficient of galvanized Al Mg products is similar to that of galvanized Al Mg products, but it changes little with the increase of friction times. Low friction coefficient is beneficial to stamping deformation. According to the requirement of high temperature assembly of some parts (350 ℃), the high temperature resistance test was carried out. The results show that there is no melting phenomenon on the surface of galvanized aluminum magnesium when heated to 380 ℃. The coating property of Zn Al Mg coated steel plate is basically the same as that of pure zinc. It can be used for electrophoresis, post spraying and color coating.

The products are mainly used in Civil Engineering (keel ceiling, perforated plate, cable bridge), agricultural livestock products (agricultural breeding shed, steel structure, steel fittings, greenhouse, feeding equipment), railway, road, power communication (transmission and distribution high and low voltage switchgear, box type substation body), automobile motor, industrial refrigeration (cooling tower, large outdoor industrial air conditioning) and other industries, It is widely used.