影响印花彩钢板涂膜厚度的因素

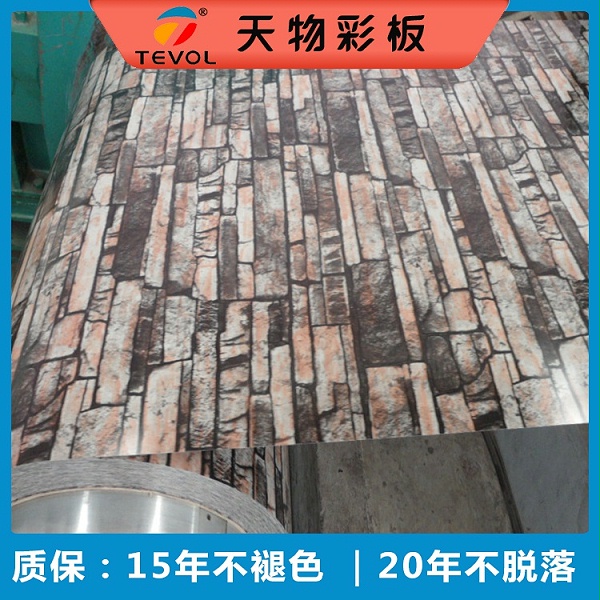

印花彩钢板由于其良好的耐腐蚀性和多种颜色,在建筑业中得到了广泛的应用。而板材的性能也会受到厚度的影响,所以在选择产品时,要仔细观察其厚度,那么影响厚度的因素有哪些呢?请看本文的分析。

1

印花彩钢板辊间压力是指物料提升辊和涂布辊之间的压力。压力越高,涂膜越低。

2循环速比-在规定范围内,循环速比越高,钢带上的油漆越多。但是,当生产线的速度降低时,涂布辊的转速会随着生产线速度的降低而降低,从而产生薄膜。

三。辊径-在相同的圆周速比下,辊径越大,薄膜越厚。

4粘度-高粘度和厚膜。在印刷彩钢板的实际生产过程中,随着季节的变化,温度的升降也会影响其粘度。

以上是影响

印花彩钢板漆膜厚度的几个常见因素。不同的因素会导致漆膜厚度的变化,因此在采购过程中,要注意厂家的生产工艺,选择正规厂家生产的板材产品,以保证板材的性能和美观符合要求。

Printed color steel plate is widely used in construction industry because of its good corrosion resistance and various colors. And the performance of the plate will also be affected by the thickness, so when we choose the product, we should carefully

observe its thickness, so what are the influencing factors for the thickness? Please see the analysis in this paper.

1. Pressure between rolls refers to the pressure between the material lifting roll and the coating roll. The higher the pressure is, the lower the coating film is.

2. Cycle speed ratio - within the specified range, the higher the cycle speed ratio

is, the more paint will be applied to the steel strip. However, when the speed of the production line is reduced, the rotation speed of the coating roller will decrease with the decrease of the line speed, resulting in thin film.

3. Roll diameter

- the larger the roll diameter is, the thicker the film is under the same circumferential speed ratio.

4. Viscosity - high viscosity and thick film. In the actual production process of printing color steel plate, with the change of season, the rise

and fall of temperature will also affect the viscosity.

The above are several common factors affecting the film thickness of printed color steel plate. Different factors will lead to the change of film thickness, so in the process of purchasing,

we should pay attention to the production process of manufacturers, and choose the plate products produced by regular manufacturers, so as to ensure that the performance and beauty of the plate meet the requirements.