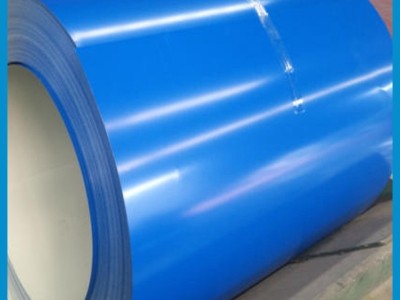

1.镀锌板,浸入熔融锌浴中的钢板,用于在其表面附着一层锌。主要采用连续镀锌工艺生产,即将轧制后的钢板连续浸入熔锌槽中,制成镀锌钢板。合金镀锌钢板。这种钢板也是用热浸法制成的,但从槽中出来后立即加热到500℃左右,形成锌和铁的合金膜。镀锌板具有良好的涂层附着力和焊接性。

它的缺点

主要包括脱落、划伤、钝化斑、锌粒、厚边、气刀条纹、气刀划伤、露钢、夹杂物、机械损伤、钢基性能差、波浪边、钢包弯曲、尺寸不当、压花、锌层厚度不当、辊印等。

产生白锈和黑点的原因如下:黑点是白锈进一步氧化形成的。

白锈的主要原因如下

(1) 钝化不良、钝化膜厚度不足或不均匀

(2) 带钢表面无油污,表面无残留水分

(3) 卷取过程中带钢表面有水分

(4) 钝化剂未完全干燥

(5) 运输或储存期间潮湿或下雨

(6) 成品的储存时间太长

(7) 镀锌板与酸、碱等腐蚀性介质接触或储存。

1. Galvanized sheet, a sheet of steel immersed in a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in the zinc melting bath to make galvanized steel plate. Alloyed galvanized steel sheet. This kind of steel plate is also made by hot dip method, but it is heated to about 500 ℃ immediately after coming out of the groove to form an alloy film of zinc and iron. The galvanized sheet has good coating adhesion and weldability.

Its disadvantages