天物彩板专注彩板16年——为工程定制提供彩板,为彩钢厂提供原材料,更多请拨打网站上方电话咨询

西安彩钢卷批发市场工业厂房的屋面板和墙板采用彩钢压型钢板时,每平方米用钢量约为5-11kg,无保温要求。当有保温要求时,可用矿棉板、玻璃棉和泡沫塑料作保温材料。压型钢板与混凝土结合,可节省木模,用作承重结构。同时,为加强压型钢板与混凝土的结合力,宜在钢板上预焊栓钉或压双向加劲肋。屋顶和墙壁的一般厚度为0.4-1.6mm; 西安彩钢卷批发市场用于承重地板或筒仓时,厚度为2-3mm或更大。波高一般在10至200毫米之间。不加筋时,高厚比应控制在200以内。采用全长屋面板时,坡度可为2-5%,挠度不应超过L/300(L为计算跨长)。

Wen he color steel profiled board is used as the house panel and wall panel of the industrial plant, the steel consumption per square meter is about 5-11kg without the requirement of heat preservation. When insulation requirements are available, mineral wool boards, glass wool and foam plastics can be used as insulation materials. The combination of profiled slab and concrete can save wood formwork and be used as load-bearing structure. At the same time, in order to strengthen the binding force between profiled plate and concrete, it is advisable to pre weld stud or press two-way stiffener on steel plate. The common thickness of roof and wall is 0.4-1.6mm; when it is used for bearing floor or silo, the thickness is 2-3mm or more. The wave height generally varies from 10 to 200 mm. When there is no stiffening, the height thickness ratio should be controlled within 200. When the full-length roof slab is used, the slope can be 2-5%, and the deflection shall not exceed L / 300 (L is the calculated span length).

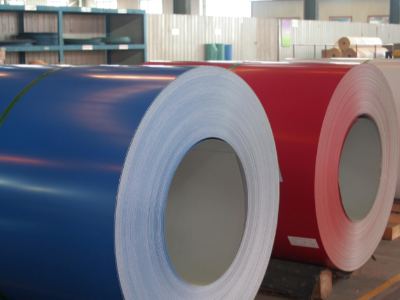

Due to the thin original plate, the quality of anti-corrosion coating directly affects the service life of the color steel profiled plate. In order to meet the requirements of processing and rust prevention, the coated steel plate shall be inspected in accordance with the relevant regulations. In general, the steel sheet can also be painted with antirust paint after pressing according to the use requirements, or the original stainless steel sheet can be used.