天物彩板全国配送——更多福州彩钢板厂家_彩钢板补漆方法_福州彩钢板多少钱一平请拨打网站上方电话咨询

1。轻质:10-14kg/m2,相当于砖墙的1/30

2。保温隔热:芯材导热系数:lambda<=0.041w/mk。彩钢板形式:成型前、卷制后、成型后多种型号,最常用的有:820、840、900等!其组成为:保护膜(现无产品)、聚酯漆、镀锌层、钢板(冷轧板和热轧板),背面顺序相同!以上分析不代表权威!

1. Light weight: 10-14 kg/m2, equivalent to 1/30 of brick wall

2. Insulation and heat preservation: thermal conductivity of core material: lambda<=0.041w/mk.

3. High strength: can be used as ceiling enclosure plate load-bearing, flexural

and compressive; general houses do not use beams and columns.

4. Bright colour: no table

Surface decoration, color galvanized steel sheet preservation period of 10-15 years.

5. Flexible and fast installation: construction cycle can

be shortened by more than 40%.

61. Oxygen Index: (OI) 32.0 (Provincial Fire Products Quality Inspection Station).

The base plate of color coated steel sheet is cold rolled, hot galvanized and electrogalvanized. The types of coatings can

be divided into polyester, silicone modified polyester, polyvinylidene fluoride and plastic sol. The surface state of color-coated steel plate can be divided into coating plate, embossing plate and printing plate. The color-coated steel plate is widely

used in the construction of household appliances and transportation industries. For the roof walls and doors of industrial and commercial buildings, such as steel structure factory buildings, airports, warehouses and refrigeration, the color-coated

steel plate is seldom used in civil buildings. It differs from plastic steel in the composition of the material. Iron-absorbing stones can be absorbed.

Strictl speaking, plastic steel and color steel in metal properties and surface treatment

can not be very good distinction, because the similarities and differences; now the market distinction is mainly in the profile structure.

Because it is a common carbon steel material, iron-absorbing stone can be absorbed. In addition, it is

added that stainless steel is the product of adding chromium element (greater than or equal to 13%) on the basis of low carbon rigidity, so the iron-absorbing stone can not be absorbed. It is not possible to prove whether iron is not contained in

the material with iron-absorbing stone.

At the end of the 1980s, color steel plate mills were built one after another in China. Most of these mills were built in iron and steel plants and joint ventures. The color steel plate process equipment

was basically imported from abroad. By 2005, the domestic color steel plate reached 1.73 million tons, resulting in excess capacity. The production capacity and equipment level of Baosteel, Angang, Benxi Steel, Shougang, Tangshan Steel, Jinan Steel,

Kunshan Steel, Handan Steel, Wuhan Steel and Panzhihua Steel are relatively high. They have successively built color steel plate units with overseas technology and annual production capacity of 120,000-170,000 tons.

At the same time, many private

enterprises invest in color steel plate production mostly using domestic equipment, production capacity is small, but fast start, low investment, products mainly for building materials, decoration industry. In addition, foreign capital and Taiwanese

capital have also landed to build color painting units, but most of them are concentrated in coastal areas. Since 1999, with the flourishing market of color coated panels, the production and consumption of color coated panels have entered a period

of rapid growth. From 2000 to 2004, production increased at an average rate of 39.0%. By 2005, the national production capacity of color coated sheets was more than 8 million tons per year, and a number of color coated units were under construction,

with a total production capacity of more than 9 million tons per year.

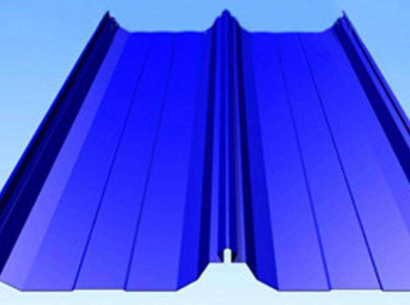

Form of coloured steel plate: before forming, coil, after forming many models, the most commonly used are: 820, 840, 900 and so on! Its composition is: protective film (no

products now), polyester paint, galvanized layer, steel plate (cold rolled plate and hot rolled plate), the same order on the back! The above analysis does not represent authority!