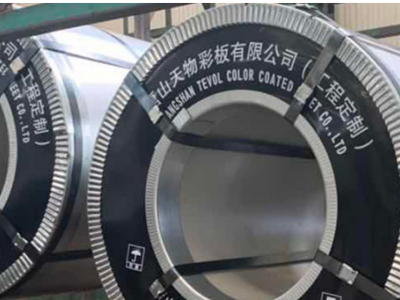

天物彩板专注彩板行业16年——成都彩钢卷批发市场什么地方请拨打网站上方电话咨询

彩钢压砖机生产的产品外观平整美观,花纹均匀,强度高,使用寿命长。广泛应用于工业和民用建筑,如车间、仓库、机务段、机务段、体育馆、展览馆、电影院等房间和墙壁。其组成部分包括:整机、PLC计算机控制系统、液压泵站系统、全自动后剪系统。彩钢压砖机设备包括:整机、PLC计算机控制系统、C型钢压砖机系统、全自动后剪系统。

本实用新型结构合理,操作方便,功能齐全,送料、成型、落胶、加热、切边、开槽、切板。采用低速计量泵,变频调速,电脑控制,计量准确。整个机组的自动控制系统采用高度集成的网络,使自动系统的性能优越。

彩钢压砖机的参数设置有很多要求。使用文本屏幕设置它们。有两种参数设置:设备参数和用户参数。设备参数有:单脉冲长度、超调量、压制距离、压制时间、切割时间等。用户参数包括:张数、长度、截面、截面、节距、截面数等。釉面砖压力机控制系统还可以完成单板切割功能。控制系统操作简单,正常的主动生产不需要后退,而是一个进步,一个压力,一个切割。精度高,每片剪切精度小于0.1mm,满足工艺要求。通过对三菱可编程高速计数区域连接编码器的实时计算,实现定长切割。

彩钢瓦压机必须采用高数脉冲输入功能,kdn-k306-24ar高数输入功能,这样AB相的抗干扰能力强。并采用定值中缀函数保证精度。

彩钢压砖机的执行部分有变频驱动电机、液压站电机、两个压砖机液压电磁阀和两个切砖机液压电磁阀。检测部分包括:检测彩钢砖长度的脉冲编码器、压型上下行程开关、切刀上下行程开关、压型上下操作按钮、切刀上下行程按钮、急停开关、液压启停开关等。

The products produced by the color steel tile press are flat and beautiful in appearance, uniform in paint pattern, high in strength and durable in use. They are widely used in industrial and civil buildings, such as workshops, warehouses, locomotive depots, aircraft depots, gymnasiums, exhibition halls, cinemas and other rooms and walls. Its components include: the whole machine, PLC computer control system, hydraulic pump station system, full-automatic after shear system. Color steel tile press equipment includes: complete machine, PLC computer control system, C-type steel press system, fully automatic rear shear system.

The color steel tile press has reasonable structure, convenient operation, complete functions, feeding, molding, glue dropping, heating, trimming, slotting and cutting into plates. It adopts low-speed metering pump, variable frequency speed regulation and computer control, with accurate metering. The automatic control system of the whole unit adopts highly integrated network, which makes the performance of the automatic system superior.