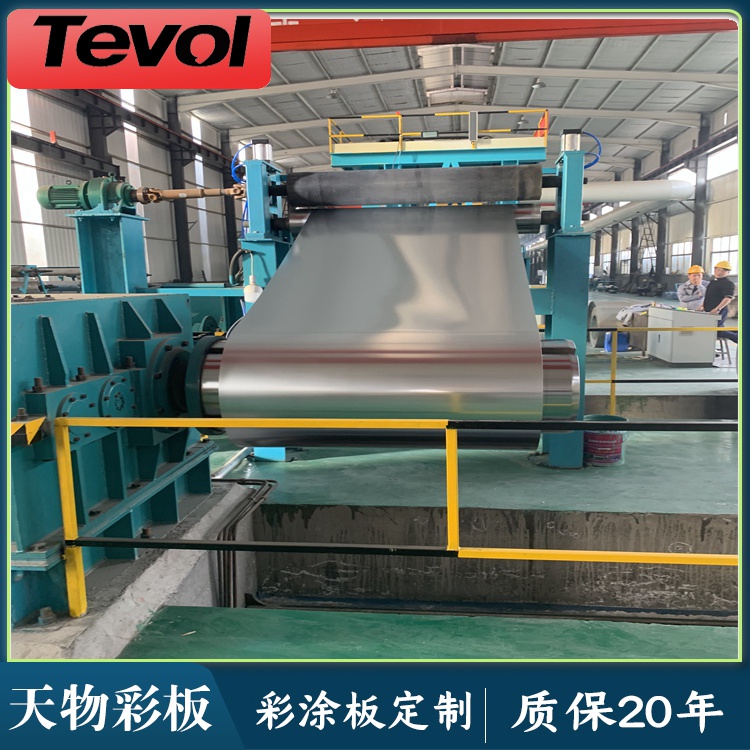

彩涂板涂膜隆起成泡或破裂成皮。开裂、起泡、脱落的缺陷通常在彩涂卷重新开卷时或在客户使用过程中发现。

开裂现象通常是在彩涂板的使用过程中发现可目测的裂纹或裂缝,裂纹从小到大,最终导致彩涂板膜层被完全破坏。脱落现象通常是涂层从钢带表面成片状掉下,伴有局部或全部剥落的现象。

(5) 彩涂卷在下线后切忌立即使用于温度变化急剧的场合。

The film swells into bubbles or breaks into skin. The defects of cracking, blistering and falling off are usually found in the rewinding of color coated coil or in the process of customer use.

Cracking phenomenon is usually found in the use of color coated sheet can be visually observed cracks or cracks, cracks from small to large, eventually leading to the film was completely destroyed. The peeling off phenomenon is usually that

the coating falls off the surface of the steel strip in flakes, accompanied by partial or total peeling off.

According to the degree of peeling off, it can be divided into: local peeling off of small pieces with a diameter of less than 5mm is called scale peeling off, local peeling off with a diameter of more than 5mm is called shell peeling off,

peeling off (or tearing off) larger than shell peeling off is called peeling off, and peeling off between the upper coating and the primer is called interlayer peeling off.

The causes are as follows

(1) Improper pre-treatment of coating results in wax, oil and water on the substrate. When it diffuses outward, the pressure will bulge the film, especially for products with poor air permeability, which affects the adhesion between layers;

people

(2) When the primer is not dry, it covers the surface coating, resulting in poor adhesion between the two layers or complete loss of adhesion( 3) The intermittent time from surface treatment before coating to coating construction is too long;

(4) There are pinholes, missed coating and bubbles in the coating, which make the coating bear stress, especially in the process of rapid cooling and film fatigue;

(5) Improper coating, too thick primer or top coating;

(6) Improper selection of coating or mismatching of bottom coating result in poor adhesion between layers, poor mechanical properties and poor flexibility of coating, which leads to cracking of coating when subjected to drastic temperature

change or external compression force.

Exclusion: no city

(1) Before coating, the substrate shall be free of wax, oil, water and other impurities, and the surface shall be free of cracks( 2) Ensure that the primer is completely cured before the top coat is applied;

(3) In order to improve the adhesion between the coatings, it is necessary to select the type of primer coating with good matching, and strictly control the thickness of the primer coating according to the construction requirements; Maturity

fever in small mobile capital

(4) Strictly control the quality of coating to avoid pinhole, bubble and other defects;

(5) Color coated coil should not be used immediately in the situation of sharp temperature change after offline.