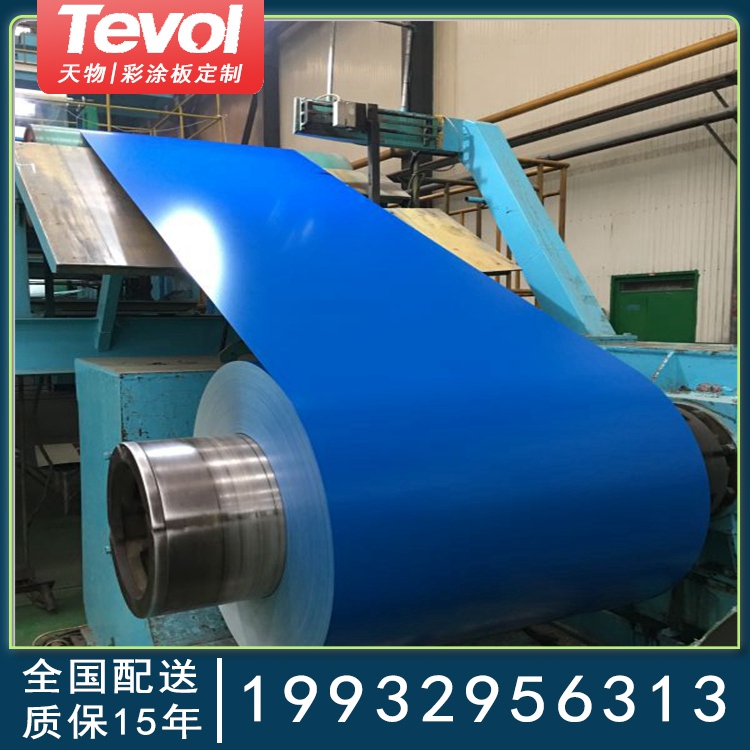

彩涂线工艺段的变频张力控制主要是固化炉区钢带的传动控制,钢带传动控制除了要满足生产线的速度匹配限制之外,还需要实现张力控制功能。张力控制主要是防止钢带在经过固化炉的时候由于张力过大而在热效应下产生拉伸变形,从而影响成品的质量。

除了通过以上模式来控制达到防止张力波动的方法外,固化炉区钢带的张力控制也可以采用一种以定子磁通和转矩为主要控制变量的新型控制技术--DTC 控制技术,其原理是交流电机传动系统中的直接转矩控制是基于定子两相静止参考坐标系,一方面维持转矩在给定值附近,另一方面维持定子融能沿着给定轨迹(预先设定的迹,如六边形或圆形等)运动,对交流电机的电磁转矩与定子磁链直接进行闭环控制。

The frequency conversion tension control of the process section of the color coating line is mainly the drive control of the steel belt in the curing furnace area. The steel belt drive control not only needs to meet the speed matching limit of the production

line, but also needs to realize the tension control function. Tension control is mainly to prevent the steel strip from stretching deformation under thermal effect due to excessive tension when passing through the curing furnace, thus affecting the

quality of finished products.

The tension control of steel strip in curing furnace area can be realized by closed-loop speed control mode. In the process section of color coating line, the tension of steel strip in suspension can be controlled by adjusting the difference

between the population speed and outlet speed of curing furnace. Because of the gravity effect of the steel strip in the process section of the color coating line, and because there is no support between the driving roller and the outlet driving roller

of the curing furnace, if the steel strip will not be deformed due to excessive tensile force in the process of movement, it must have a certain degree of suspension, And in the whole process of equipment operation, it must be ensured that the sag

is in an appropriate fluctuation range. The essence of speed difference regulation is a kind of tension PID control mode, which needs to rely on additional tension sensor feedback as the basis of speed regulation. Although this control method is relatively

simple, it is not ideal to achieve stable tension control effect in the process of system start / stop or acceleration / deceleration, which is easy to affect the quality of coating drying.

In addition to the above control mode to prevent tension fluctuation, a new control technology DTC control technology with stator flux and torque as the main control variables can also be used for the tension control of steel strip in curing

furnace area. Its principle is that the direct torque control in AC motor drive system is based on stator two-phase static reference frame, On the one hand, it keeps the torque near the given value, on the other hand, it keeps the stator melt energy

moving along the given track (such as hexagon or circle, etc.) to directly control the electromagnetic torque and stator flux linkage of AC motor.