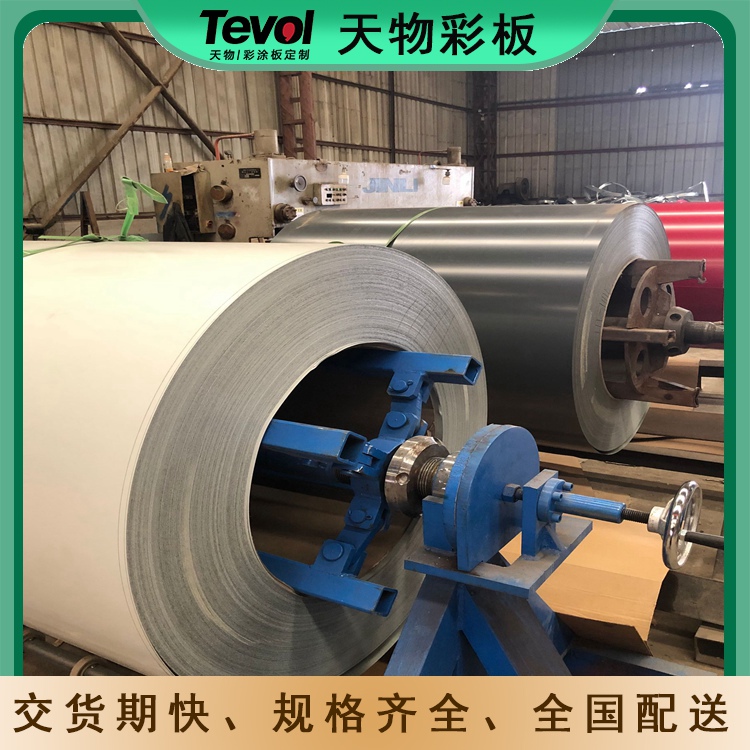

彩钢卷上涂料的区别

天物彩板专注彩涂板行业17年——彩钢卷上涂料的区别_广东省彩涂板厂家排名请拨打网站上方电话咨询

众所周知,彩钢板卷在金属板上涂了一层漆。然而,油漆之间存在差异。不同油漆的彩钢卷的用途也大不相同,正如汽车的彩钢卷与窗户的彩钢卷不同一样。下面介绍各种油漆及其用途。

1.醇酸树脂涂料

醇酸树脂由多元醇与多元酸和脂肪酸酯缩聚而成。其性能与改性植物油的种类和油度密切相关。醇酸树脂有很多种。

它们的特点如下:① 它们具有良好的柔韧性、附着力和机械强度。② 该颜料在涂料中具有良好的分散性。③ 该涂层具有良好的耐用性和耐光性。④ 漆膜饱满,耐溶剂、耐热性好,耐水性差。

该涂料广泛应用于建筑工程门窗、木家具、船舶、桥梁、机电产品、光学仪器、各类汽车等。

2.丙烯酸树脂涂料

丙烯酸树脂是由丙烯酸或甲基丙烯酸酯、眼睛、酰胺和其他单体聚合而成。由于单体的选择不同,可以制备热塑性和热固性涂料。

热塑性涂料硬度好,颜色浅,不黄变,耐久性好。主要用于航空工业所需的耐候性好、保光性好的铝合金表面。

热固性涂料具有优异的物理机械性能,表面丰满度好,耐候性强,保色性好,亮度高,硬度高,具有一定的耐水性和耐油性。它们大部分是通过高温烘烤固化的。适用于汽车、轻工产品、家用电器等。

3.聚酯树脂涂料

聚酯树脂主要由二醇和二元酸组成。含聚酯的涂料可获得多种物理性能组合,即既有硬度又有柔韧性。它们还具有优异的耐化学性、耐热性和良好的成形性。主要用于建筑内衬、运输车等。

4.硅改性精细涂

它由丙烯酸或聚酯和硅化物组成。具有良好的外观耐久性、不粉碎性和光泽保持性。尽管灵活性有限,但它们适用于一般中等轧制成型。典型用途为外部场合,尤其是预制工业建筑和住宅侧墙。

As we all know, the color steel coil is coated with a layer of paint on the metal plate. However, there are differences between the paints. The purposes of the color steel coil made of different paints are also very different, just as the color steel

coil made of automobile is different from the color steel coil made of window. The following introduces various paints and their uses.

1. Alkyd resin coating

Alkyd resin is formed by polycondensation of polyols with polybasic acids and fatty acid esters. Its performance is closely related to the type and oil degree of modified vegetable oil. There are many kinds of alkyd resins.

Their characteristics are as follows: ① they have good flexibility, adhesion and mechanical strength. ② The pigment has good dispersibility in the coating. ③ The coating has good durability and light retention. ④ The paint film is plump, with good

solvent resistance and heat resistance, but poor water resistance.

The coating is widely used in building engineering doors and windows, wood furniture, ships, bridges, electromechanical products, optical instruments, all kinds of cars and so on.

2. Acrylic resin coating

Acrylic resin is polymerized by acrylic acid or methacrylate, eyes, amides and other monomers. Due to the different selection of monomers, thermoplastic and thermosetting coatings can be made.

Thermoplastic coating

has good hardness, light color, no yellowing and good durability. It is mainly used for aluminum alloy surface with good weather resistance and light retention required by aviation industry.

Thermosetting coatings have excellent physical and mechanical

properties, good surface fullness, strong weather resistance, good color retention, high brightness, high hardness, certain water and oil resistance. Most of them are cured by high temperature baking. It is suitable for cars, light industrial products,

household appliances, etc.

3. Polyester resin coating

Polyester resin is mainly composed of diol and dibasic acid. Polyester containing coatings can obtain a variety of combinations of physical properties, that is, they can have both hardness

and flexibility. They also have excellent chemical resistance, heat resistance and good formability. They are mainly used for building linings, transporters, etc.

4. Silicon modified fine coating

It is composed of acrylic acid or polyester

and silicide. It has good appearance durability, non pulverization and gloss retention. Although limited in flexibility, they are suitable for general medium roll forming for construction. Typical uses are external occasions, especially prefabricated

industrial buildings and residential side walls.