GB/T 13448-2006 彩色涂层钢板及钢带试验方法--耐雾实验

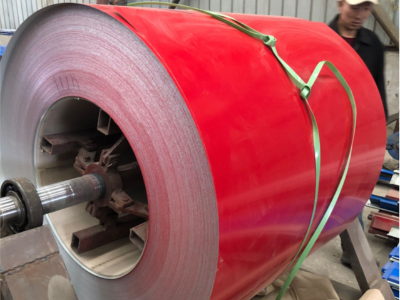

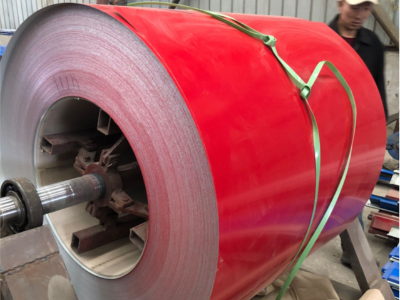

天物彩板专注彩板行业16年——太原红白彩钢板_山西彩涂卷库存请拨打网站上方电话咨询

盐雾腐蚀试验箱、一个或两个雾化喷嘴、一个盐溶液储罐、一个空气饱和器和一个无油无尘送风系统

在涂层上切割线的刀,刀角为30°、pH计或精密pH试纸(测量精度为0.3)。称取50g氯化钠试剂,用蒸馏水溶解,稀释至1000ml,混匀。GB/T 13448中配制的盐溶液的pH值应在6.5-7.2之间。

pH值可以用pH计或精密的pH试纸测量。溶液的pH值可用盐酸或氢氧化钠溶液调节。盐雾收集器:罐内至少放置两个收集器,一个靠近喷嘴,一个远离喷嘴。

集热器建议采用直径为10cm的玻璃长颈漏斗和量筒

试样:尺寸为75mm×150mm,同一试样数量不少于3个。试样表面应平整,无油污、损伤和毛刺

氯化钠溶液浓度为(50±5)g/L,冷凝后溶液的pH值在6.5-7.2之间。每80㎡水平面平均每小时收集的降雾量为(1.0-2.0)ml(按24小时收集的盐雾量计算)。样品应放置在与垂直方向成15°^-30°的位置,使盐雾能够自由地下沉到所有样品上。试验箱达到试验条件后,进行连续喷雾。

结果测定:试验结束后,将试样从盐雾箱中取出,用清水冲洗,用冷空气吹扫,立即评定。根据GB/T 1766-1995,试验结果应评定泡沫等级和锈蚀等级,并取平行试样的最差值作为试验结果。

Salt spray corrosion test chamber, one or two atomizing nozzles, one salt solution storage tank, one air saturator and one oil-free and dust-free air supply system

A knife for cutting line on the coating, with a knife angle of 30 °, pH meter or precision pH test paper (measuring accuracy of 0.3). Weigh 50 g of sodium chloride reagent, dissolve it with distilled water and dilute it to 1000 ml, and mix it well. The

pH value of the prepared salt solution shall be between 6.5-7.2 in GB / T 13448.

The pH value can be measured by pH meter or by precise pH test paper. The pH value of the solution can be adjusted by hydrochloric acid or sodium hydroxide solution.

Salt mist collector: at least two collectors shall be placed in the tank, one close to the nozzle and one away from the nozzle.

10 cm diameter glass long neck funnel and graduated cylinder are recommended for collectors

Sample: the size is

75 mm × 150 mm, and the number of the same sample is not less than 3. The surface of the sample shall be flat, free of oil stain, damage and burr

The concentration of sodium chloride solution is (50 ± 5) g / L, and the pH value of the solution after

condensation is between 6.5-7.2. In every 80 ㎡ horizontal plane, the average amount of mist reduction collected per hour is (1.0-2.0) ml (calculated by the amount of salt mist collected in 24 hours). The sample shall be placed at 15 ° ^ - 30 ° from the

vertical direction in such a way that the salt mist can freely sink on all the samples. After the test box reaches the test conditions, continuous spray is carried out.

Result determination: after the test, take the sample out of the salt spray

box, wash it in clean water, blow it with cold air, and evaluate it immediately. According to GB / T 1766-1995, the foaming grade and rust grade shall be evaluated for the test results, and the worst value of parallel samples shall be taken as the test

results.